on top of the wood flooring.

UV Coating Finishing System

UV coating finishing system is a technology that integrated different type of UV coatings to provide a better

surface protection for the hardwood flooring. These layers of coating have different functions and characteristics,

which are related to one another and indispensable from each other. Below table shows the different types of

UV coating that available and the function:

UV coating finishing system can be developed and vary by deciding how many layers of the coating

and also the combination of different types coating according to the function that you need. The total

layer of coating can be as simple as 4 layers to 10 layers or even more!! To develop an UV coating

finishing system is almost same like to create a recipe for a meal. Every manufacturer can created their

unique system according to customer needs and make them outstanding from the competitors.

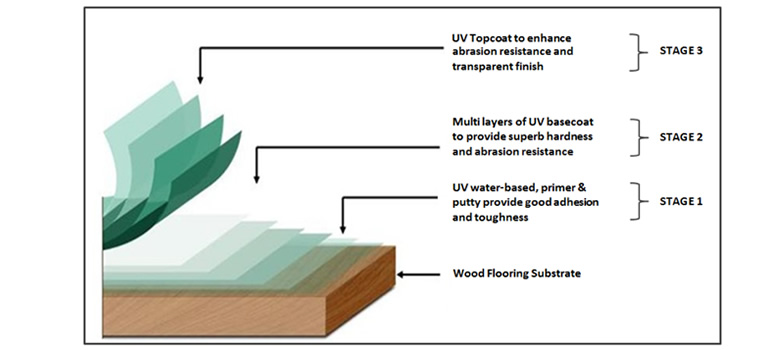

Although the layers and the combination coating can be changed, but the basic “sequence” need to

be followed. Below picture shows the feature or the basic “sequence” for a UV coating finishing system:

From the picture shows above, basically UV coating finishing system can be divided into three different stages.

Stage 1 is playing a very important function for the adhesion and toughness of the final finishing for the timber

flooring. The coating that needs to use in this stage is basically UV water-based, UV primer and UV putty.

Manufacturer can decide how many layers and combination that needs to use.

Physical properties like hardness, abrasion resistance, scratch resistance and etc. are contributed from stage

2. There are various of UV basecoat can be used in this stage and again manufacturer is able to decide

how many layers and the combination to achieve clients requirement.

Finally come to the finishing stage which is stage 3. We only advice to use UV topcoat for this stage to control

the transparency, surface smoothness and glossiness. There are two type of UV topcoat which are popular use

in the market: UV ceramic topcoat and UV aluminum-oxide topcoat. Timber flooring chooses UV ceramic

topcoat in order to enhance the scratch resistance for the surface finishing. Strongly suggest the layer for topcoat

is between 2-3.

Wood is a precious resource from the nature. Wood itself already has a natural beauty appearance, UV coating

is just an extra step to enhance the appearance and give extra protection in order to make the hardwood flooring

more durable. With this say, UV coating is just like a cosmetic for the wood flooring!!

Below are some pictures to show the production line and the coating application machine:

Advantages of UV Coating

Compared to other types of coatings, the most significant feature of UV Coating is the fast

curing speed. It can be cured between 0.05s – 0.1s under UV light irradiation. Traditional coatings

like solvent-based coating and water-based coating need several hours or days to fully cure.

And due to the fast curing speed, UV Coating can be prefinished in the production line, the overall

production time is save, hence increase the production efficiency. Prefinished Wood flooring with UV

Coating can be installed immediately on site; there is no sanding, no waiting for the finish to dry compare

with traditional unfinished wood flooring. Therefore, we can save the site installation time as well.

There is no Volatile Solvent in the composition of UV Coating; this is complaint with environmental friendly.

Solvent-based coating normally content 30% – 70% of inert solvent, during their curing process almost all volatile

into atmosphere, this will harm the environment. The UV Coating is different, UV Coating is 100% solid content,

all the compositions cross-link during the UV curing process and there is no/low volatile organic compounds (VOC)

that volatile into atmosphere, which in turn, considerably reduces air pollution, harm to the human body and fire hazards.

UV Coating is considering low wastage in application as well. UV Coating is 100% solid content, all the compositions

during the curing process cross-link during the UV curing process and form a solid protection film; therefore it is fully

utilize the coating.

Besides that the application machine for UV Coating are designed to recycling the coating.